Cupra, with its parent company SEAT, has installed a new press at its Martorell plant in northern Spain that is claimed to be one of the most advanced in the world - and it will go on to produce body panels for various electric vehicles (EVs) in the wider Volkswagen Group.

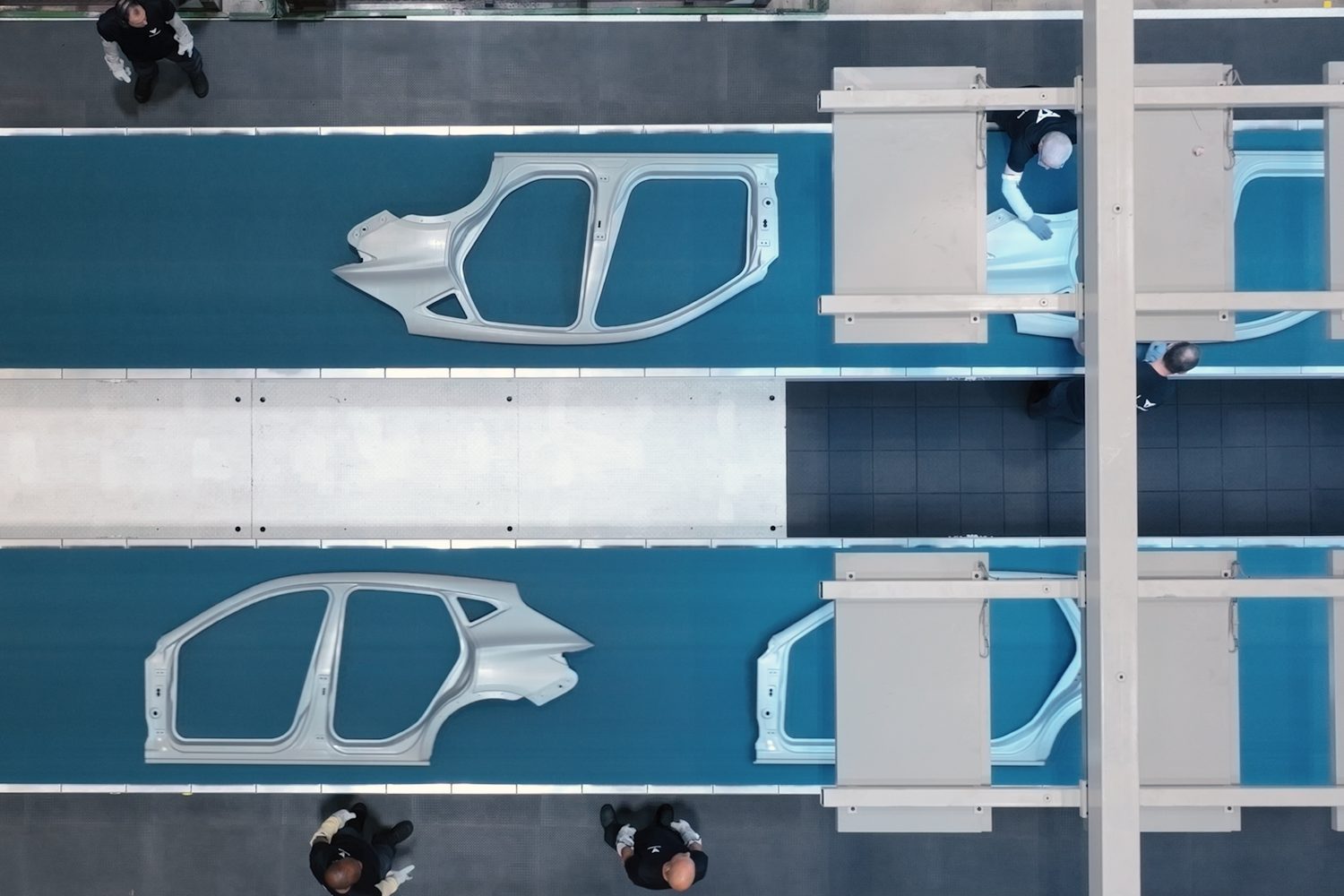

Efficient, powerful and connected, this new PXL press will be used to churn out up to four million body parts per annum, principally for the Cupra Raval and Volkswagen ID. Polo.

High productivity

The PXL press at Martorell is already stamping parts for Cupra's current vehicles, as well as SEATs too. Alicia Molina, the director of production process engineering for Cupra and SEAT, said: "Thanks to its 15 strokes per minute, we can stamp more parts in less time, with maximum efficiency.”

It also reduces the time needed to change the dies, allowing up to 15 changes per day to manufacture different parts for different vehicles. Jose Arreche, the director of the plant at Martorell, explained: "By fully automating this process, we have managed to decrease the time it takes to change dies to just five minutes between finishing the last part in a series and starting production of the first in the next one.”

Doing the groundwork

Cupra is keen to play up what a technical feat it was simply installing the PXL press in the first place. It's so heavy that it exerts 81,000kN of force on the ground, so the press sits atop a nine-metre-deep pit and 20-metre concrete-pile foundations, which is about as high as a seven-storey building. It took 40 months of development and construction work, as well as keenly organised logistics, just to get the PXL into its current position.

Molina added: "Communication and cross-functional work among the production process [was essential] - engineering, maintenance, production, logistics, IT, prevention and finance teams played a key role in the success of this mega-construction project.”

Production processes of the future, now

Around 3,000 data points can be extracted from each and every stamping in the PXL press, which is where it demonstrates its heightened connectivity. Over to Molina again: "We're currently developing two systems that will be key to interpreting this huge flow of data, and gathering detailed information about production control and maintenance.”

This data can then be used to make predictions about and optimise all production processes at Martorell going forward.

Training essential

Such a high-tech installation means the people who work on the PXL press have been faced with a significant transition period, said Arreche: "Training was an essential part in preparing us for this change at all levels. We've changed our mindset, and now we're ready for the new electric era.”

The PXL press is part of a programme of change for SEAT S.A., in which it is aiming to turn Spain into a European hub for EVs. The company has invested €10 billion into the country's electrification, as part of the Future: Fast Forward project.

Martorell will begin producing 100 per cent EVs, including the Cupra Raval, from 2026 onwards.