BMW frames the iX3 as a major step in its circularity strategy. And the closer you look, the clearer it becomes that the car is only the opening move in a broader, long-term shift.

BMW has been talking about circularity for several years, but the iX3 is the first model built on the architecture intended to carry that idea into high-volume production.

Hesse presents it plainly: "The iX3 is the lowest-CO₂ electric car we have built so far.”

BMW claims to be halfway towards its self-set 2030 target of reducing emissions by nearly 40 megatons against 2019 levels. Those numbers come from BMW's own modelling, and they're coming about thanks to reengineering the vehicle platform itself. But it's not about just one car.

"It's an architecture… it's scalable,” Hesse says, noting that BMW has designed the platform so the same circularity principles will appear in all future models based on it. In practice, this means earlier consideration of material separation, recyclability and reduced energy use in manufacturing.

For buyers in Ireland, the iX3 is effectively the first real-world look at this new engineering direction.

BMW keeps its "Technology Open” position

While some rivals have announced end-dates for internal combustion, BMW remains committed to producing a mix of petrol, diesel, hybrid and electric powertrains depending on region and demand.

"We are open for all drivetrains the customer wants,” says Hesse. "We think we can reach our 2030 goals even with combustion engines still in the mix.”

From a global perspective, this is understandable. EV adoption is uneven, and BMW sells in markets where charging infrastructure remains limited. But it does create a contrast with the new iX3, which moves BMW firmly into dedicated EV platforms rather than multi-purpose ones adapted from combustion models.

According to Hesse, this shift is driven by necessity: "The battery, the structure, the geometry - everything can be optimised without compromise.”

For Ireland, this means future electric BMWs should arrive as fully optimised EVs, not conversions of existing platforms also used for internal-combustion-engined cars.

Hydrogen is still in development, too

BMW continues to invest in hydrogen, even if it remains a niche technology for now. The iX5 Hydrogen project demonstrates that the company hasn't abandoned the idea, despite the lack of consumer-ready infrastructure.

"Hydrogen research began long before the iX5,” Hesse notes. "Even hydrogen combustion engines were explored 20 years ago.”

BMW isn't claiming hydrogen is a near-term solution for the Irish market or anywhere else. The company simply wants to keep the option open, should wider energy and infrastructure developments ever make it viable.

Recycled materials without compromising quality?

One of the biggest challenges for premium carmakers is using more recycled and secondary materials without affecting perceived quality. BMW says this is non-negotiable.

"Every recycled material must meet the same or higher standard than primary material,” Hesse says.

Artificial leathers and polymers are claimed to now match or exceed the tactile feel of virgin materials, but the bigger challenge is ensuring quality and standards across BMW's vast supplier network - around 2,700 tier-one suppliers and more than 65,000 in total.

In practice, BMW's biggest material-related gains come not from visible cabin materials but from upstream metals and battery content.

"Battery cells are around 50 per cent of the footprint. Aluminium and steel are around 20 per cent. Plastics are much smaller,” Hesse explains.

So while interior materials matter for marketing, the heavy lifting happens in battery sourcing and metal production.

Battery strategy: higher energy density

BMW claims significant improvements in battery efficiency and material sourcing in the iX3, resulting from higher energy density and a greater use of secondary materials - especially lithium, nickel and cobalt.

"Secondary materials require less energy and have a lower CO₂ footprint,” says Hesse.

BMW says the iX3's battery contains about 50-per-cent-recycled lithium, nickel and cobalt in specific streams, and roughly 20 per cent secondary material overall.

However, availability is a future concern.

"There will be a battle for recycled materials,” Hesse admits.

This feeds into BMW's push to design vehicles that are easier to dismantle at the end of their useful life. If recyclers can extract materials more efficiently from a BMW, BMW reckons it stands a better chance of securing those materials for future production - a practical, not ideological, form of circularity.

What about ethical sourcing and the limits of oversight?

Criticism around the labour and environmental impacts of mining battery materials remains widespread. BMW says it enforces strict contractual standards and responds quickly to concerns.

"If we get to know something is not right, we act immediately,” Hesse says.

The company relies on supplier audits and independent checks, though no global supply chain is fully transparent. Complications also arise from geopolitical risks and the need for redundancy in sourcing.

"Since Covid, we've added suppliers across different continents to keep our plants supplied,” Hesse notes.

This push for "local for local” sourcing is likely to grow, including the European supply chain that serves Ireland.

Debrecen: BMW's first fossil-free production plant

The iX3 is produced in Debrecen, Hungary - BMW's first plant designed to run entirely on renewable energy. The facility is powered by 25 per cent on-site solar and 75 per cent purchased renewables.

BMW says Debrecen was planned from the outset with sustainability as a pillar. The company claims the iX3's production-phase emissions now align with those of an optimised combustion X3 - a notable milestone.

However, upstream emissions from material processing still dominate the overall footprint, meaning production-side improvements must be matched by raw-material reductions to hit long-term targets.

Do buyers of premium cars prioritise sustainability?

Whether sustainability sells cars is still an open question. Hesse argues that while buyers don't necessarily ask for detailed accounting, they simply expect the manufacturer to be acting responsibly.

"If you pay that much money, you expect the sustainability aspect.”

For BMW, this expectation is becoming part of the brand identity. Whether customers in Ireland actively choose a car based on recycled content is unclear, but the broader trend suggests premium manufacturers are being judged increasingly on their environmental transparency.

Concept features vs. production reality

Some of BMW's earlier sustainability concepts included ideas such as etched exterior badging and mono-material sections designed for easy recycling. Not all of these features translated to the production-ready iX3.

The etched badges, for instance, worked only because the concept cars lacked paint.

"With paint, it's very different,” Hesse notes.

But the broader philosophy of reducing material types and simplifying disassembly is present in the iX3, even if the more radical styling features remain conceptual for now.

What the iX3 represents for BMW

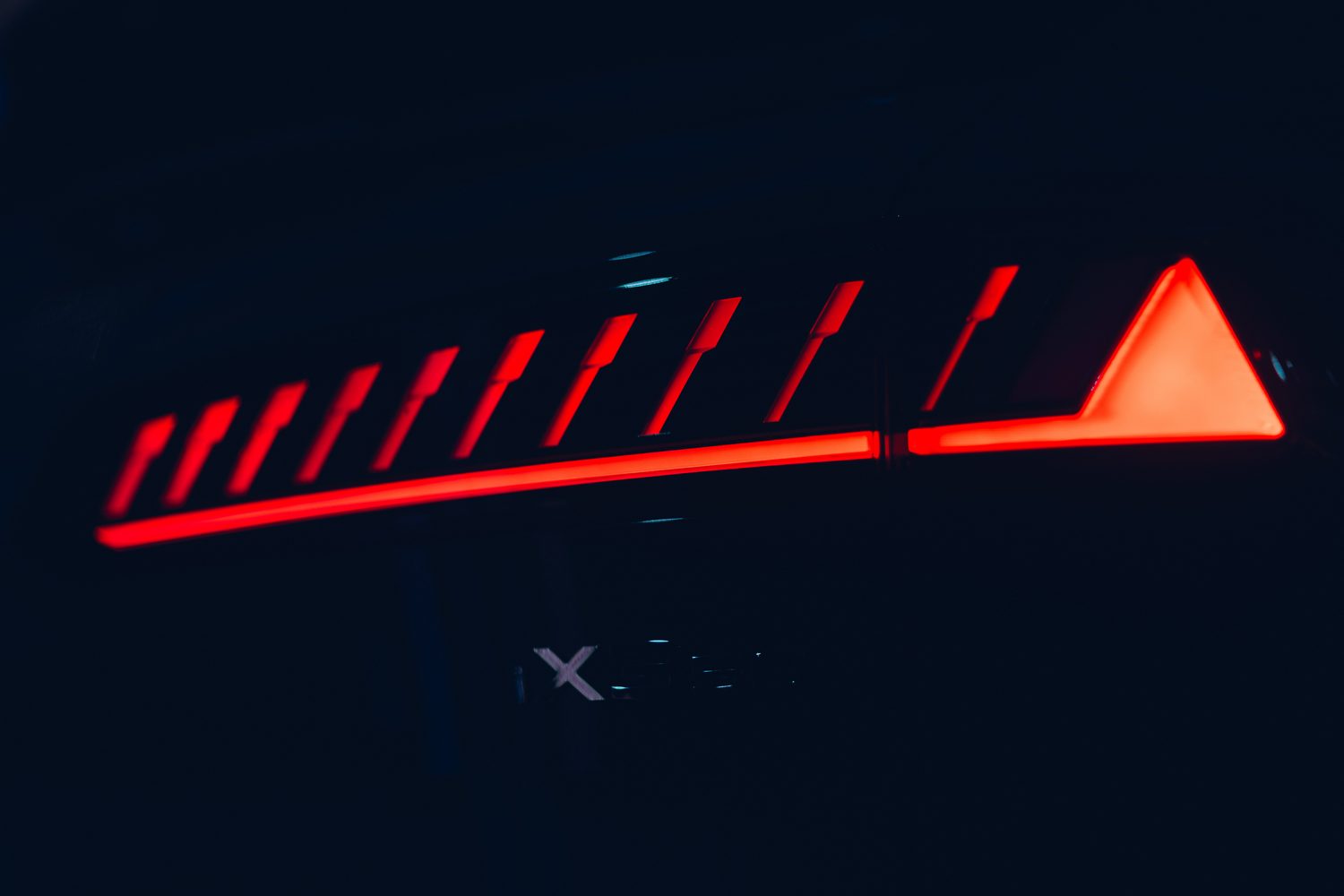

The iX3's significance goes beyond its spec sheet. While the original BMW i3 was the company's first purpose-built electric model, the iX3 represents the next phase: a high-volume EV developed on BMW's modern electric-led architecture.

It incorporates higher levels of recycled materials in its battery, is produced using renewable energy and offers a preview of how future BMWs will be engineered for easier disassembly and improved material recovery.

At the same time, BMW continues to support multiple powertrain technologies, faces the same recycled-material shortages as the rest of the industry and must navigate a global supply chain that is increasingly unpredictable.

The iX3 doesn't resolve all of this, but it does show where BMW's engineering and sourcing priorities are moving. And it previews what to expect of a whole new generation of BMWs. Indeed, it won't be long before we see the 2026 BMW i3, an all-electric 3 Series saloon using the same platform as the iX3.