BMW has lifted, ever so slightly, the veil of secrecy surrounding its all-important, all-electric 'Neue Klasse' family of EVs. The name harks back to the BMW 1500 of the 1962, long famed as the car that saved the company, and which would eventually develop into the first 3 Series. The path of the next Neue Klasse is likely to be the same, kicking off as it will a whole new family of BMW models.

Huge leap in technology

While we don't know much about the car (or cars?) itself, we do know a bit more now about its batteries. Three years ago, BMW opened a new battery development centre in Munich, and some of the first fruits of its labours will be the new high-tech batteries that will power the Neue Klasse. "The newly-developed sixth generation of our lithium-ion cells will bring a huge leap in technology that will increase energy density by more than 20 per cent, improve charging speed by up to 30 per cent and enhance range by up to 30 per cent," according to Frank Weber, member of the Board of Management of BMW AG responsible for Development. "We are also reducing CO2 emissions from cell production by up to 60 per cent. These are big steps for sustainability and customer benefits."

BMW says that it has already awarded two multi-billion-dollar contracts to build these batteries at a mass scale, and the German company says that it will build "battery cell factories with our partners, each with an annual capacity of up to 20GWh, at six locations in North America, Europe and China."

Green power

"To meet our long-term needs, we will be building battery cell factories with our partners, each with an annual capacity of up to 20GWh, at six locations in key markets for us" said Joachim Post, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network. "We have also reached agreement with our partners that they will use a percentage of secondary material for the raw materials lithium, cobalt and nickel, as well as utilising green power for production, to ensure CO2-reduced manufacturing."

Based on what batteries cost to build right now, BMW estimates that this new family of power cells will be around 50 per cent cheaper to make. That's a big step towards the company's goal of making EVs as affordable to build as current internal combustion models.

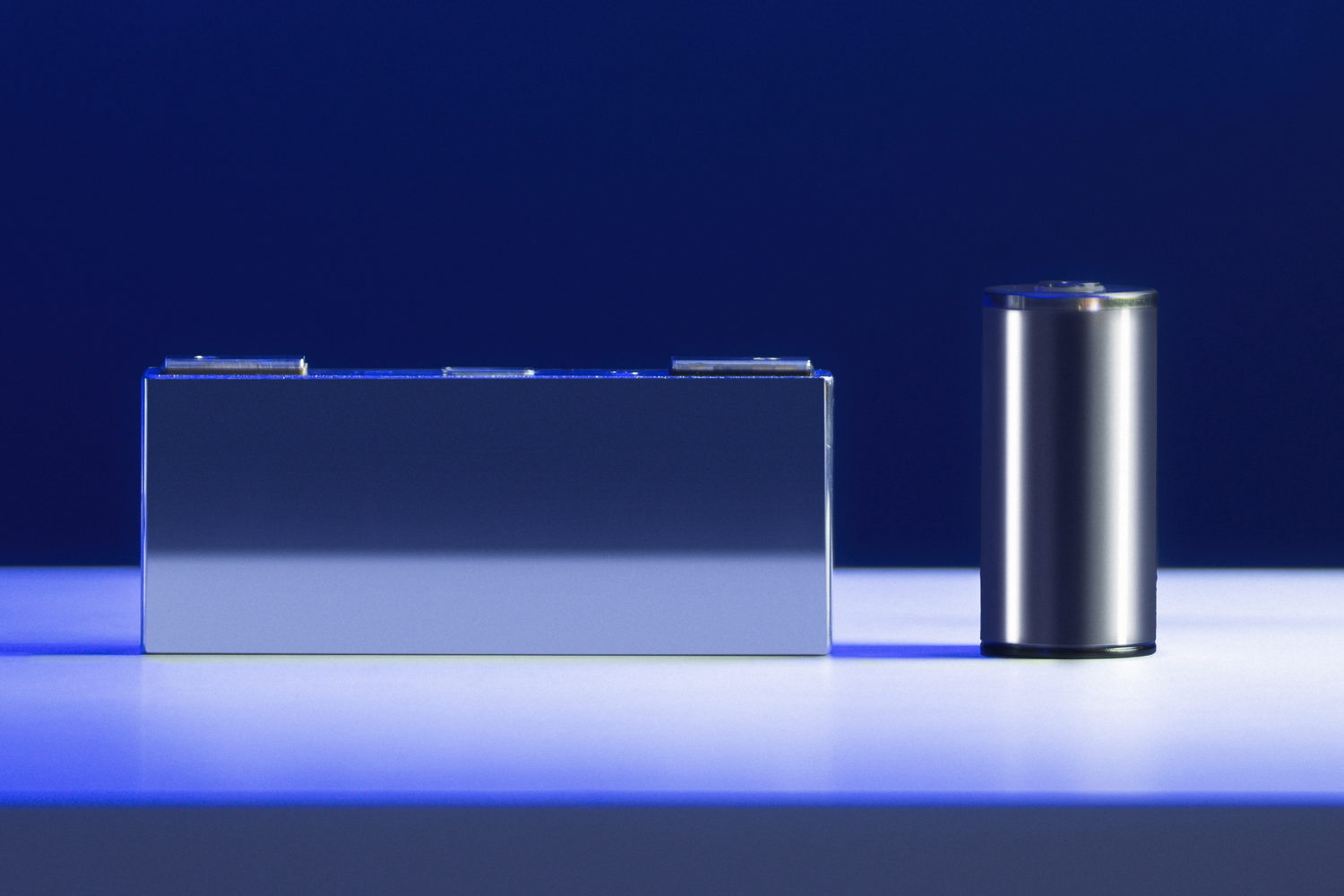

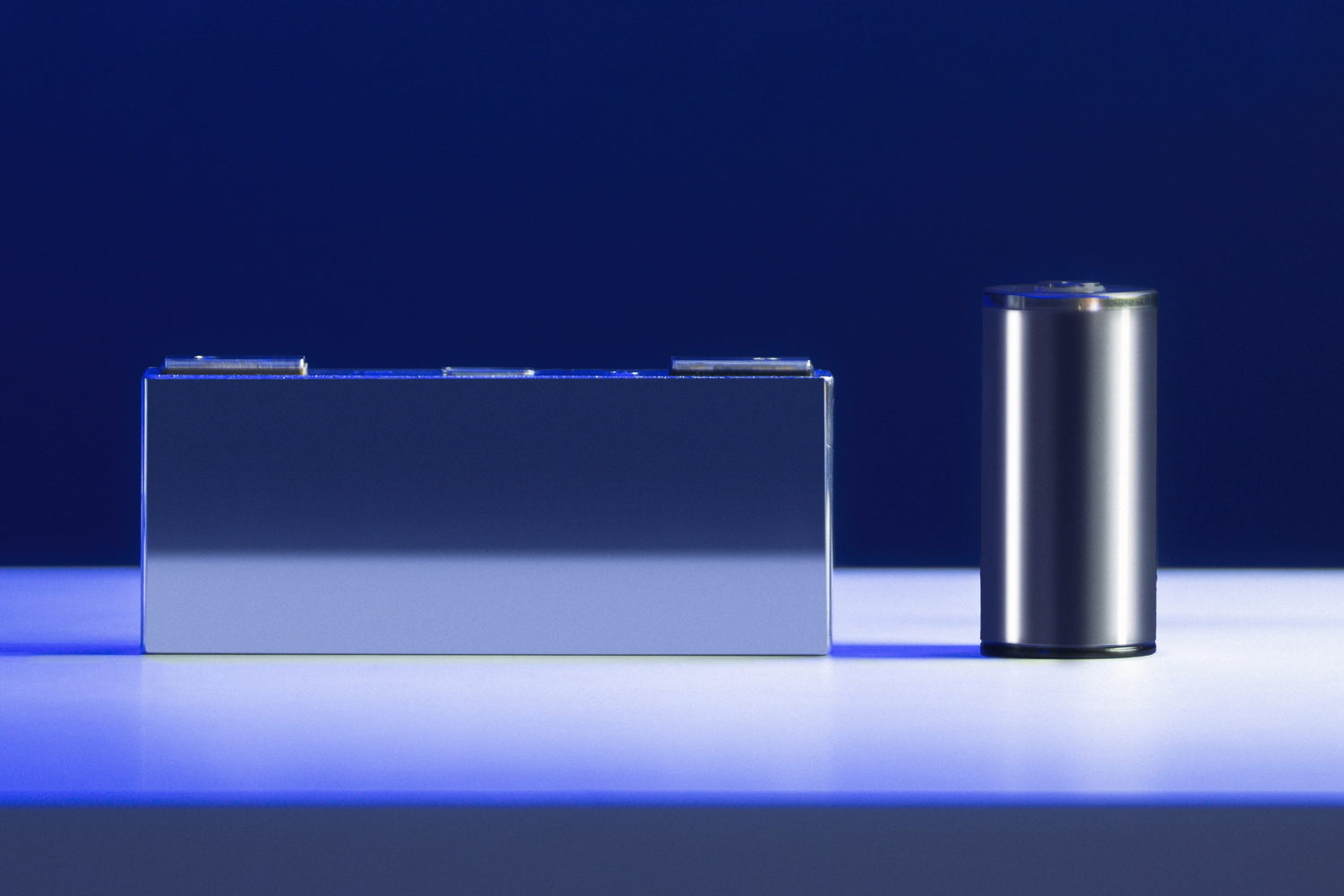

To get there, BMW says that it has "fundamentally refined the cell format and cell chemistry", which not only makes the batteries more efficient to build, but can potentially boost the range of a given vehicle by 30 per cent compared to current models. The new BMW round cells come with a standard diameter of 46 millimetres and two different heights. Compared to the prismatic cells of the fifth BMW battery cell generation, the nickel content in the sixth-generation BMW round cells is higher on the cathode side, while the cobalt content is reduced. On the anode side, the silicon content will be increased. As a result, the cell's volumetric energy density will improve by more than 20 per cent.

These new battery packs are also designed to be more tightly integrated into the car's body, helping to save weight and space. The packs are also being designed to have a charging capacity of 800 volts, which means quicker rapid charging. As with range, rapid charging times can be cut by as much as 30 per cent.

Recycled material

The packs will also contain more recycled material than is currently used, which, combined with other production methods, is expected to reduce the carbon footprint of each battery by 60 per cent compared with current designs. Eventually, the plan is for each battery pack to be not only fully recyclable, but fully recycled. The cobalt and lithium that BMW does need to use, new, will come from certified mines to try and allay fears over worker exploitation. The idea is also to develop the design of these new packs so that they can use lithium-iron phosphate parts, eliminating the need for costly cobalt altogether. Beyond that, BMW plans to start making solid-state batteries by the end of the decade, but that technology remains unproven.

As for the Neue Klasse itself, while we still don't know what it will look like, nor what variants will be spun off from the initial design, BMW has massive plans for it. By 2030, BMW projects 50 per cent of its global sales to come from fully-electric models. That's actually much lower than the predictions of other car makers, interestingly.