Volkswagen has announced that its Hannover factory, where it currently builds the Transporter van, will expand over the next few years to start making large electric SUV passenger cars.

New luxury electric SUVs

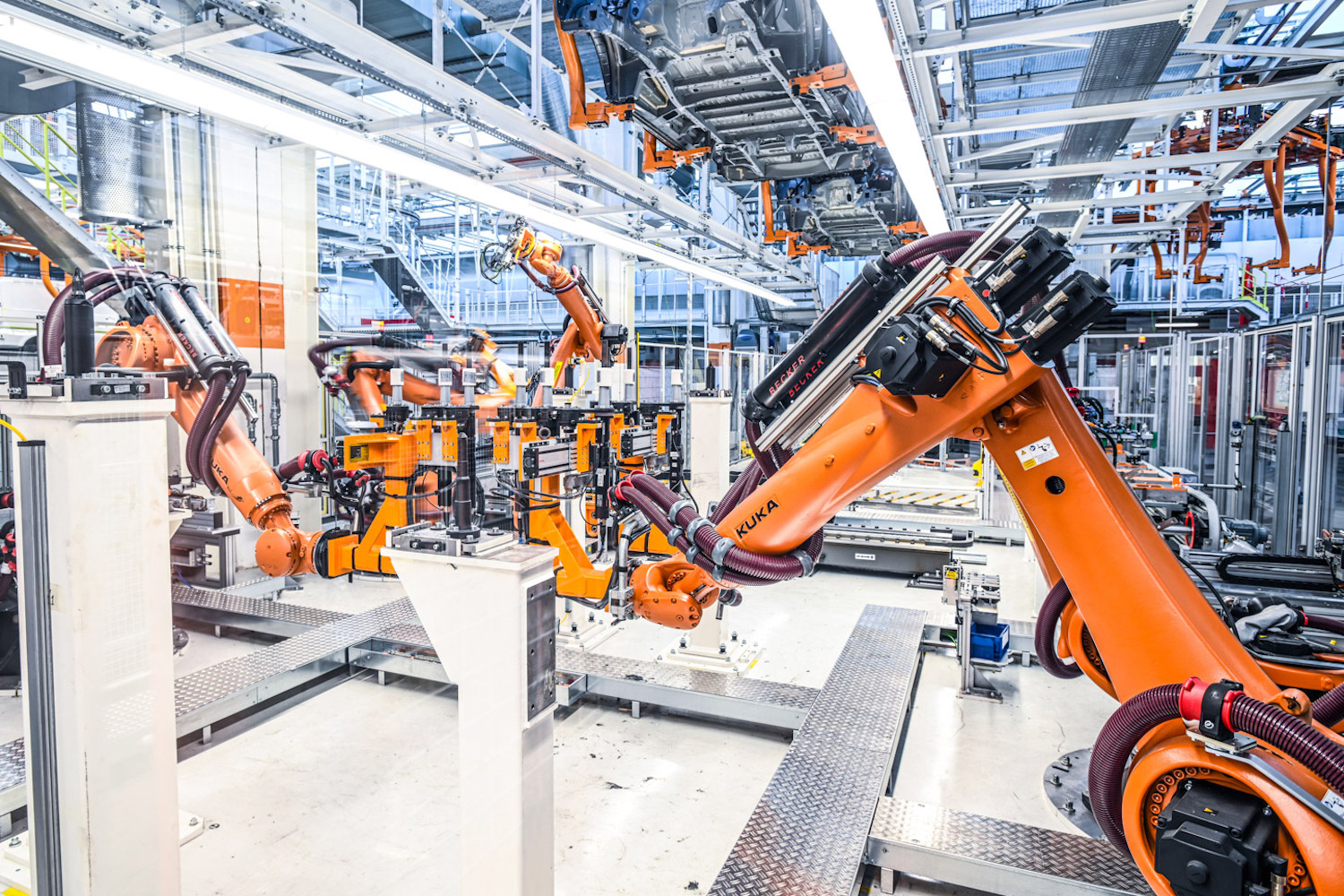

The plant has already been earmarked for the production of electric versions of the Transporter, as well as the oh-so-cool retro-style ID.Buzz electric MPV and van, but the expansion into passenger car making is a real vote of confidence in the factory's ability to turn out high-quality products.

"Our main plant in Hannover is becoming the production site for three completely new premium electric vehicles in the Group", explains Dr Carsten Intra, Chairman of the Board of Management of Volkswagen Commercial Vehicles. "These D-SUVs are genuine flagship projects: premium, 100 per cent electric and highly automated. Today's decision by the Volkswagen supervisory board is thus an important milestone for our high-tech site and a great show of faith in the productivity of our team. We were able to secure this decision in favour of our location with our assured efficiency and top level of production quality. My thanks are due today to every one of our colleagues whose work made this pioneering decision possible."

€680 million investment

Hannover will get a €680 million investment to build these new cars, and a new production line is part of the plan. The first IDS.Buzz electric van is destined to roll off the line in 2022, but this new plan involves the site becoming a 'multi-brand' factory - that's interesting, and reading between the lines it seems likely that Audi and possibly even Porsche models may well end up being made here - Porsche will be replacing its current Macan in 2022 with an all-electric car, while Volkswagen has a large ID.5 SUV in the works.

Bertina Murkovic, VWCV Works Council Chair: "The competition with other Group brands was tough. But ultimately, backed by our site agreement and with our expertise in quality production we were able to win these products for Hannover. A level of utilisation that, as agreed, ensures our employment levels along the demographic curve has thus been secured for the coming years. The new Multivan, the ID.BUzz and now the D-SUVs are our portfolio for this decade. No greater security than this could be established at the current time for the location or the workforce."

The moves at Hannover are part of a massive €33 billion investment in electric vehicles by Volkswagen and its various brands. Having started with the Audi e-Tron quattro and this year's Volkswagen ID.3, the number of electric cars being made by the group will explode in the next couple of years, with the ID.4 SUV, the Skoda Enyaq, the SEAT El Born, the Audi e-Tron GT, the ID.5 SUV, an electric Passat replacement, and more.

75 all-electric models

In all, Volkswagen plans to introduce some 75 fully-electric models across its various brands by 2028. Volkswagen has kicked off the building of batteries at what will become its own 'Gigafactory' for electric vehicle (EV) power sources in the next five years. The new plant at Salzgitter (about an hour south-west of Volkswagen's home plant in Wolfsburg, in Germany) won't actually start mass-producing EV batteries until 2023, but a pilot line has already opened up to start work on figuring out the best ways to build lots of batteries and build them fast.

Dr. Stefan Sommer, Volkswagen's head of procurement, said: "Bringing together the development, testing and pilot production of battery cells in Salzgitter marks a further milestone in the Volkswagen Group's comprehensive electric offensive. By pooling know-how at this site, we are making sure we drive forward our own activities to further advance the development of battery cells as a key component in electrification, develop new standards and swiftly transition them to series production."

Frank Blome, who will head up the battery centre of excellence at Slazgitter, said: "Today's commissioning of the pilot line is an important step on the road to building a Gigafactory at the Salzgitter site. We will further deepen our knowledge of production processes within a short space of time. That is important in order to shape future developments and thus secure performance and costs as well as quality. The experience gained will also contribute to mastering the entire value chain for lithium-ion batteries - from raw materials through production to recycling."