Thousands of visitors have had the pleasure of walking the hallowed ground of Ferrari's factory in Maranello. What could be sexier than seeing shiny new Ferraris driving out the doors? Many of those visitors probably don't realise that most of the cars begin life up the road at the Scaglietti plant. That's where we are for the day at an 'aluminium workshop'.

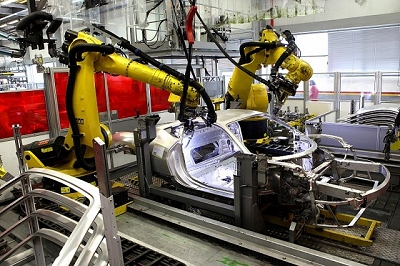

The 'workshop' word usually sends dread into the hearts of attendee journalists, but even the most cynical would smile as they enter the gates of the Scaglietti plant to be greeted by row upon row of aluminium spaceframe. These form the backbone of the 458 Italia and Spider, the California and the 599 GTB. Completed spaceframes and body panels arrive here from local suppliers to be assembled as a complete body in white (BIW) before heading down the road to Maranello for finishing off.

Ferrari is putting Scaglietti forward as a 'hub of aluminium excellence', which may seem a little curious given the apparent adoption by other parties of carbon fibre as the material of the future for sports cars. We're here because Ferrari wants to show us why it thinks that aluminium is far better suited to the majority of its cars.

Somehow, a 56-slide PowerPoint presentation isn't as dull as it should be when you're sitting in a Ferrari factory. The walls are adorned with bits of F1 cars, prototype alloy wheels and huge photographs of some of the company's most iconic models. The 288 GTO and F40 are depicted and given that these pioneered road-car composite materials for Ferrari, why is it now, decades later, stating that carbon fibre is not its way forward?

The main reason seems to be the difficulty with producing the number of cars Ferrari wants to make. The Scaglietti plant puts out 28 Ferrari bodies a day from the V8-engined range alone. That simply would not be feasible in carbon fibre - not economically at least. Along with that Ferrari is proud of the fact that it continually makes improvements to the BIW during a car's life cycle; this would be very costly to do with carbon fibre tooling. Finally, Ferrari explains why aluminium cars are easier to repair after an accident.

A bewildering amount of technology goes into the design and production of Ferrari's aluminium cars. One engineer tells us nonchantly that 100,000 hours were spent on Finite Element Analysis (FEA) of the 458 Spider's chassis alone, in a bid to optimise the weight and rigidity. Indeed, lessons learned from that will soon be implemented into the production of the 458 Italia too.

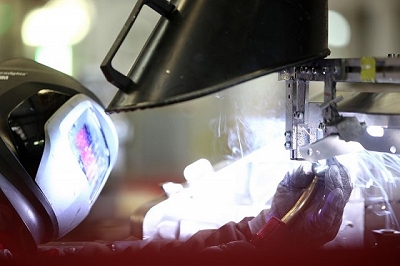

Ferrari gave us a glimpse at where it's going next with aluminium. The short version is that it is looking for a 15 - 20 per cent reduction of mass over the next five years. At that time a new generation car will be unveiled signalling an anticipated step reduction of another 20 per cent in mass. Those appear to be huge changes without the use of carbon fibre. Along with more widespread use of various aluminium alloys Ferrari is actively researching more efficient means of joining and creating components. For instance, MIG (Metal Inert Gas) welding will eventually be replaced by CMT (Cold Metal Transfer), which has much less effect on the mechanical properties of the material. Adhesives will be employed more in the future too, in conjunction with new riveting techniques. Design of components has been freed up considerably by the introduction of new manufacturing processes, such as superplastic forming, which have been made possible by the use of new alloys. Like I said: a bewildering amount of technology and we're only scratching the surface here.

Don't worry, Ferrari isn't giving up on carbon fibre completely. It acknowledges that its mechanical properties are highly desirable, so it will continue to investigate using them, but for now they're likely to be used only on limited production models, such as the 2015 Ferrari F70 for instance...