It's a common misconception that tackling the emissions from cars is all about the exhaust pipe. Switch all cars to electric power, and the problem will be solved, right? True, we do have to do just that - take away the emissions that we cause from driving about, but there's so much more to vehicle emissions than just that.

It's not just about driving; it's also about manufacturing and, of increasing importance, 'un-manufacturing'. If a car can be made up of recycled metals, plastics and other materials, and if those materials can be more easily removed, reused and recycled, then old cars can become new cars, just like the aluminium in the can of fizzy drink in your hand right now might have been a can several times before. This idea of a closed loop of manufacturing, circular car making, is what will truly drive down vehicular emissions.

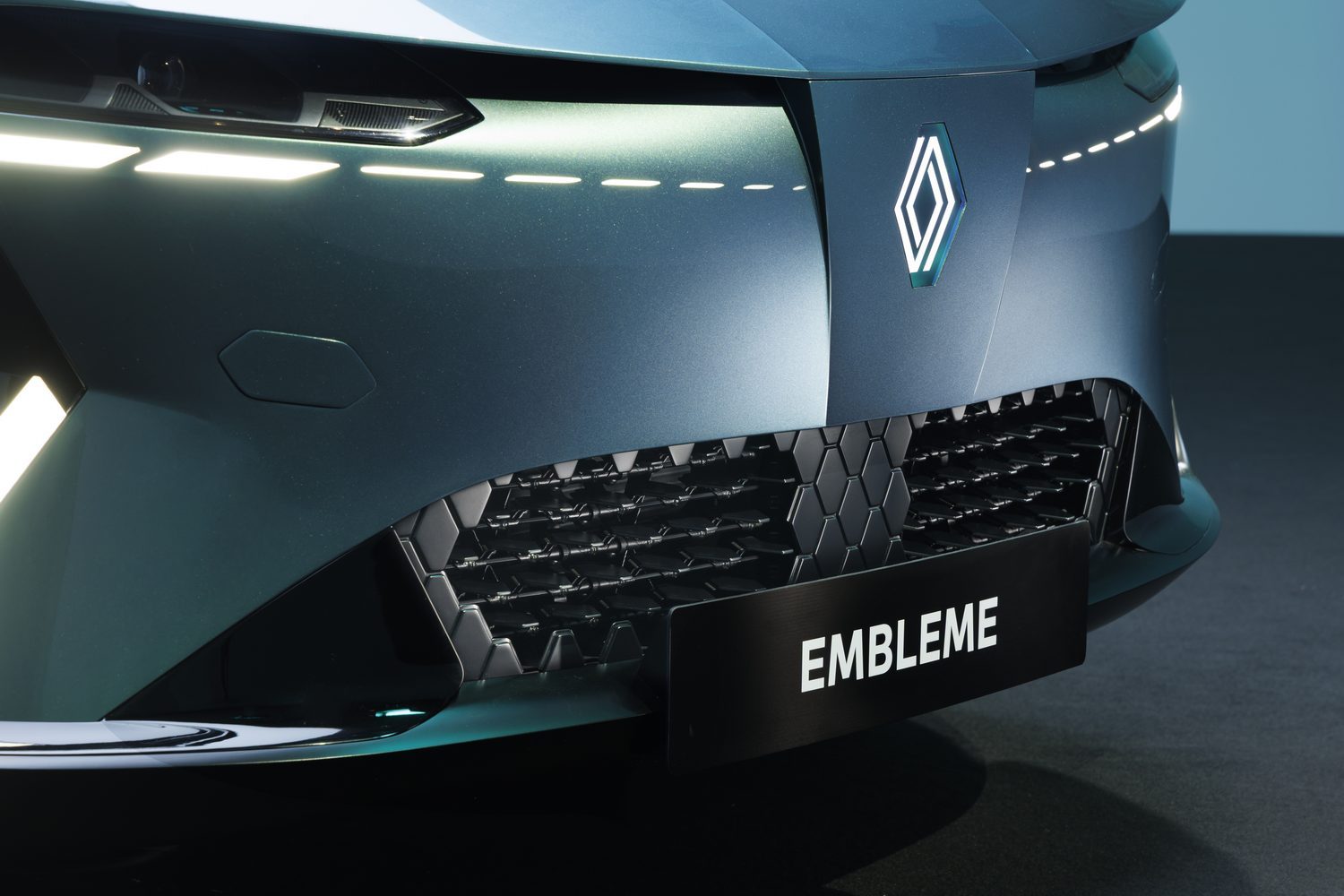

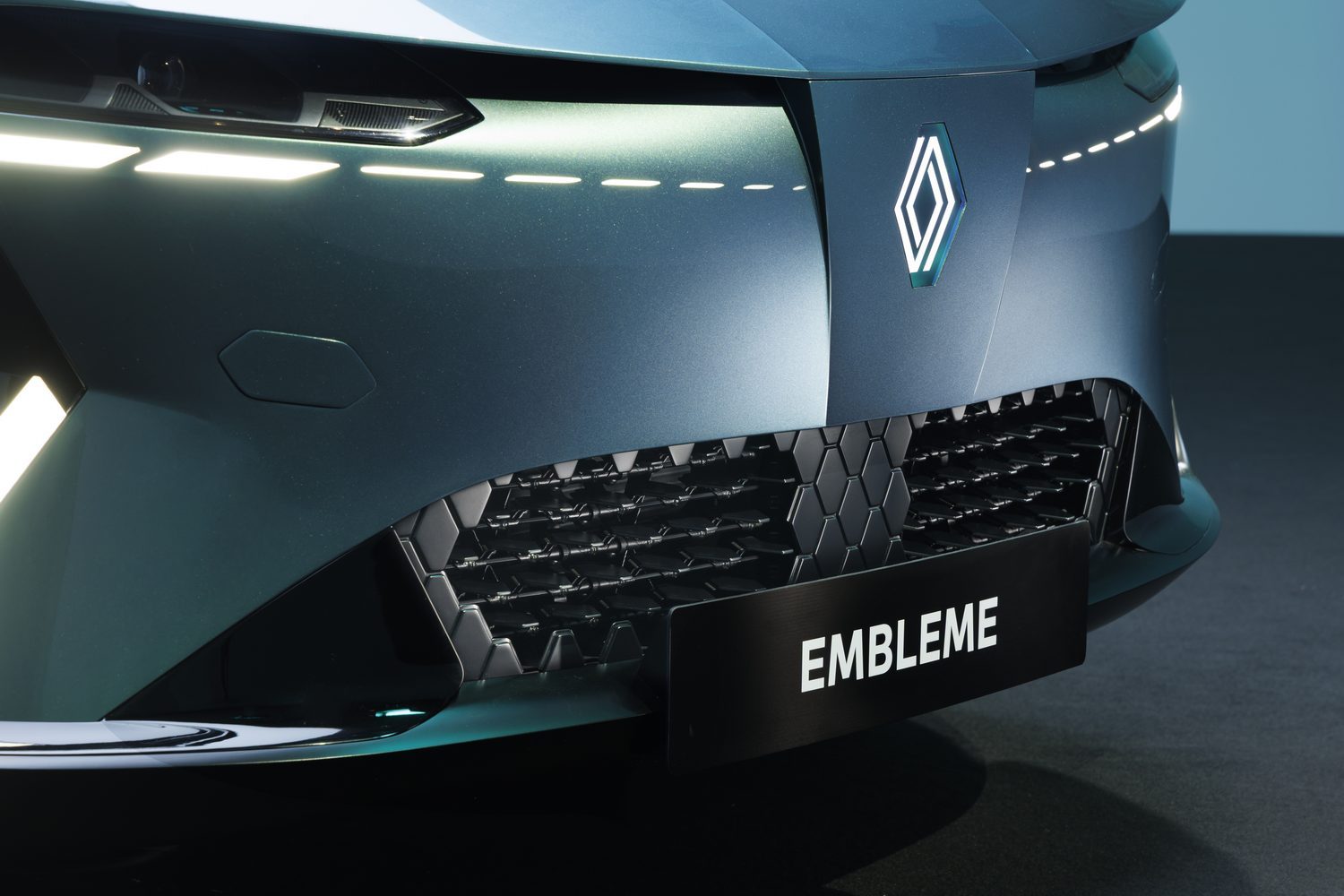

It's precisely this that Renault is exploring with its new Emblème concept car. Look at the Emblème on a motor show stage, or even in these photos, and it strikes you as a handsome car, but fairly conventional. You can see little touches of the current Renault Megane and Scenic E-Tech models in its styling, for instance.

Is there more to this than its dramatic design?

But under the skin, this Emblème might just be representative of a revolution in manufacturing. And indeed, so too is its skin because all of that's recyclable too. Developed by Ampere, Renault's electric and recycling subsidiary, the idea behind the Emblème is that it should achieve a 90 per cent reduction in its lifetime CO2 emissions - compared to a baseline of the cars Renault was building in 2019.

According to Renault, “Emblème explores intelligent, credible and viable combinations, particularly in terms of resources, materials, production, use and end-of-life recovery. In this way, it achieves a 70 per cent reduction in the carbon footprint for the production of all parts. At the same time, 50 per cent of the materials used to build the car are recycled and virtually all the materials used are recyclable at the end of their service life.”

“The ambition of the Renault Emblème project was to achieve maximum decarbonisation by designing a car that is attractive, efficient, family-friendly, comfortable, high-tech and versatile in use. More than a concept car, it's a demo car on the road that's a pleasure to look at, to be in and to drive - a real invitation to travel,” says Fabrice Cambolive, CEO of the Renault Brand.

The figures underpinning the Emblème's environmental performance are potentially staggering. Take a current Renault Megane E-Tech, one of the best current EVs on sale. Over its lifetime, including being built, being used and being recycled at the end of its life, the estimate is that each Megane will result in the emission of around 25 tonnes of CO2. That's a massive improvement on a comparable 2019 Renault Captur crossover with a petrol engine, which is expected to account for some 50 tonnes of CO2 emissions in its lifetime.

How does the Renault Emblème compare?

The Emblème? Five tonnes. And that's not a figure which Renault has plucked from the air; it has been calculated and audited by independent experts from IFPEN (Institut Français du Pétrole et des Energies Nouvelles).

So, how do you design a vehicle that cuts the total lifetime CO2 emissions of a very efficient current electric car by 80 per cent? You start from first principles...

Cléa Martinet is the Vice President for Sustainability in the Renault Group and said that the Emblème “Embodies decarbonised and resource-respectful mobility, conceived from design to end of life, in an ecosystemic and collective manner, with our partners and suppliers across the entire value chain. In addition to providing a preview of upcoming design silhouettes, it incorporates technologies developed by Ampère, which will be gradually introduced in the next generations of vehicles.”

As Renault puts it, the Emblème's CO2 reductions start with the first stroke of the designer's pencil and encompass all the components of the vehicle. So, the Emblème has been designed to be as light as possible, and while 1,800kg isn't quite flyweight, but for a long-range zero-emissions car with lots of space inside, it's not bad at all.

Sure, but what else can be done?

Then, you start looking at materials. Seven materials and components account for 90 per cent of the car's carbon footprint: battery, steel, aluminium, polymers, electronic components, tyres, fuel cell and tank. To bring down the CO2 emissions associated with all of those parts and components, Renault has worked with suppliers such as AKWEL, Autoneum, ArcelorMittal, CEA (French Alternative Energies and Atomic Energy Commission), Constellium, Dicastal, Forvia, Forvia / Hella, Michelin, OPmobility, STMicroelectronics, Valeo and Verkor. With all of those companies and contributors, the plan was to find a 70 per cent reduction in the carbon footprint of parts production: steel, aluminium, plastics, tyres, glass and electronics.

Small savings, even tiny ones, in each individual area all add up. So AKWEL, the company that makes the Emblème's door handles, not only designed an aerodynamically efficient door handle, but it also reduced the overall weight of the finished part by 60 per cent and reduced the number of parts needed to make the handle and the mechanism by 50. Even so, the handle - electronically activated - still responds in 0.1 seconds when you put your hand on it.

Carbon savings were also found in the raw steel of the Emblème's body. Renault worked with ArcelorMittal to develop advanced high strength steels (AHSS) and 'press hardenable steels' (PHS), which helped to find an eight per cent reduction in the weight of the body structure. The steel for the B-pillar has been made using renewable energy only, and using 75 per cent recycled steel. Autoneum designed acoustic insulation panels made from recycled cutoffs, using renewable electricity, reducing the carbon footprint of its components by 70 per cent.

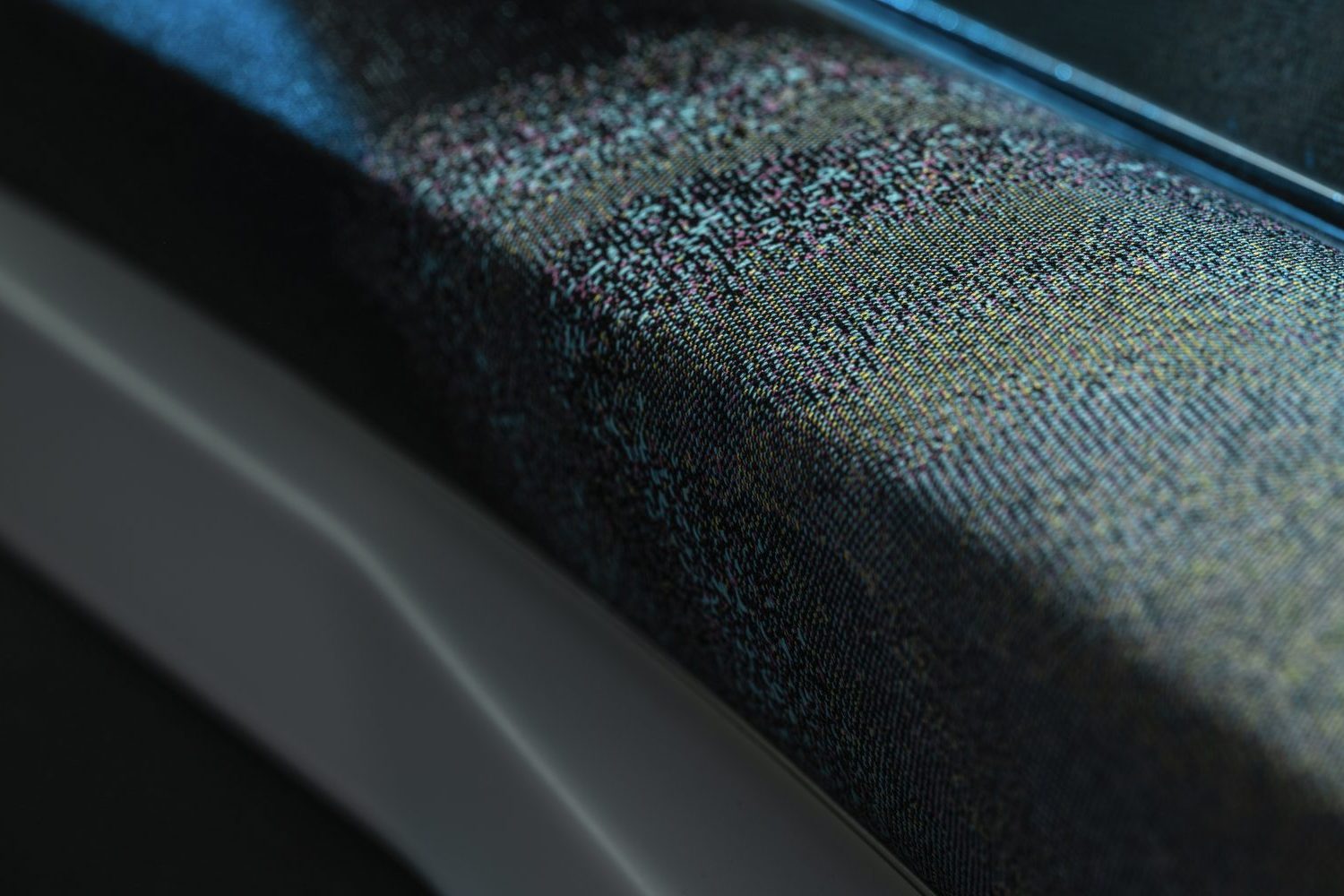

The list goes on and on - recycled aluminium that uses just five per cent of the energy needed to smelt new stuff; thin and light alloy wheels made from 70 per cent recycled material; interior materials made from linen and even pineapple, which act as carbon sinks; interior components designed to snap into place without welding or adhesive; headlights which need 80 per cent less material than usual; specially designed Michelin tyres which are designed to reduce their carbon footprint by 40 per cent; a hydrogen tank made from carbon fibre...

Wait, a hydrogen tank? Isn't the Emblème an electric car?

Not quite. Renault has recognised that many people are still spooked by the thought of doing long journeys in an EV and having to deal with slow or unreliable public chargers (and this is in France, where public charging is leagues ahead of Ireland...). Nonetheless, the Emblème does use a 40kWh battery, with a range of “several hundred kilometres, more than enough for everyday journeys” as Renault puts it.

There are also solar cells on the roof which can top up the battery a little on sunny days or allow the air conditioning to be used while the car is parked. For longer journeys? A hydrogen fuel cell, which, for a journey of 1,000km, would require just two two-minute refuelling stops, as the Emblème's fuel cell system delivers a range of up to 350km.

The Emblème's drive system is based around a wound-rotor electric motor - without rare earths - powered by a dual-energy system: the 40kWh NMC (Nickel Manganese Cobalt) battery housed under the floor, and a 30kW PEMFC fuel cell running on low-carbon hydrogen from a 2.8kg tank under the bonnet. Renault claims that on a drive from Paris to Marseilles, the Emblème would produce 75 per cent of the electricity needed from its hydrogen system, with the only emissions being water vapour.

Is the world really ready for hydrogen?

Many will point out the current lack of a hydrogen fuel infrastructure - certainly true of Ireland - though in France, efforts and investment are underway to change that. As Renault puts it: “Huge progress has been made in recent years on the energy density of the batteries used in all-electric cars, but this is still not enough to equal ICE vehicles in terms of range and journey time. For this reason, the engineers of Emblème also explored the possibilities offered by hydrogen. Odourless, colourless and non-corrosive, hydrogen is a gas that produces electricity when burned in a combustion engine or oxidised in a fuel cell, a process that releases only water. Proven solutions exist for storing and producing hydrogen, while charging time at a hydrogen pump is fast: one kilogram per minute, a figure set to increase in the future.”

Talk us through the interior

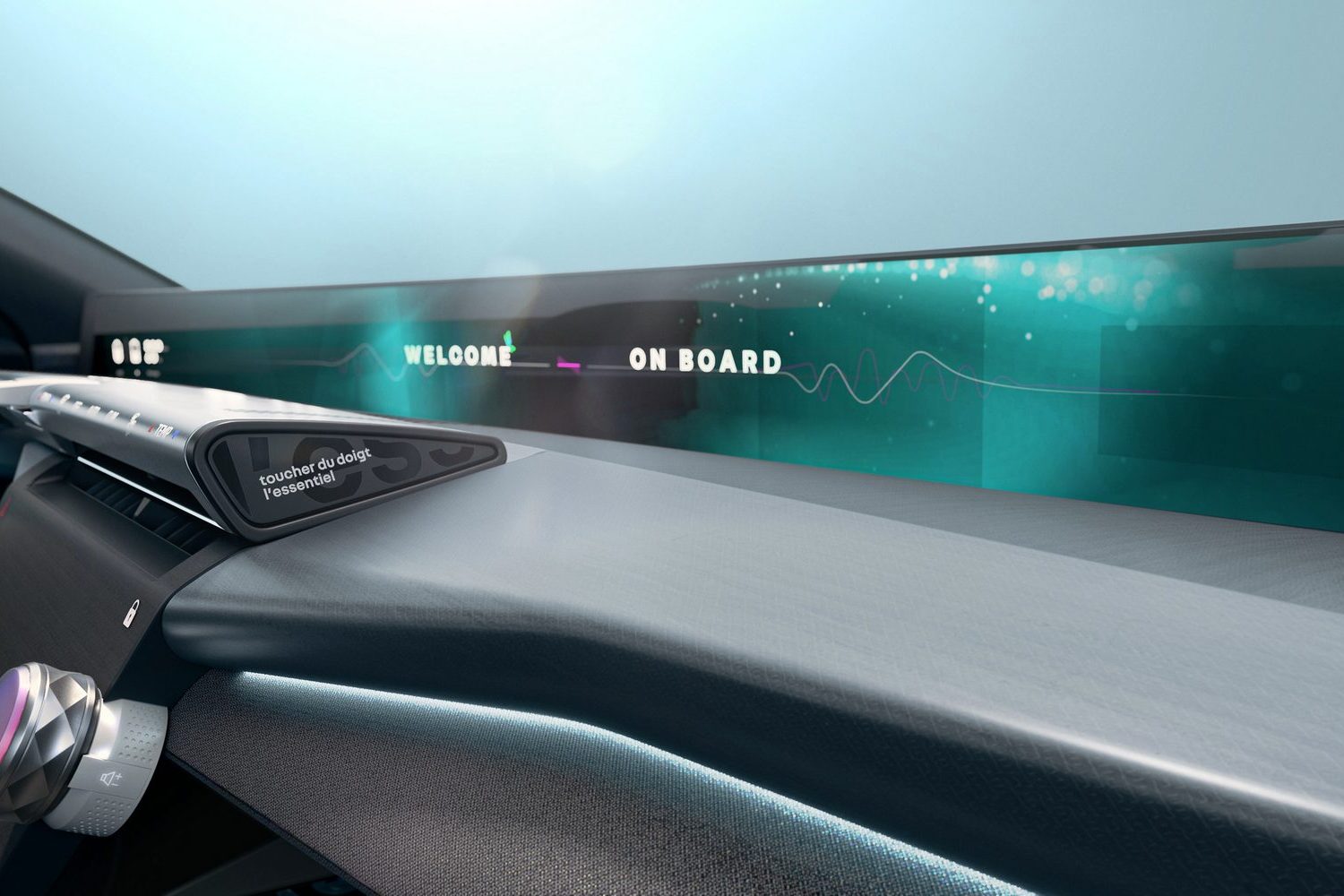

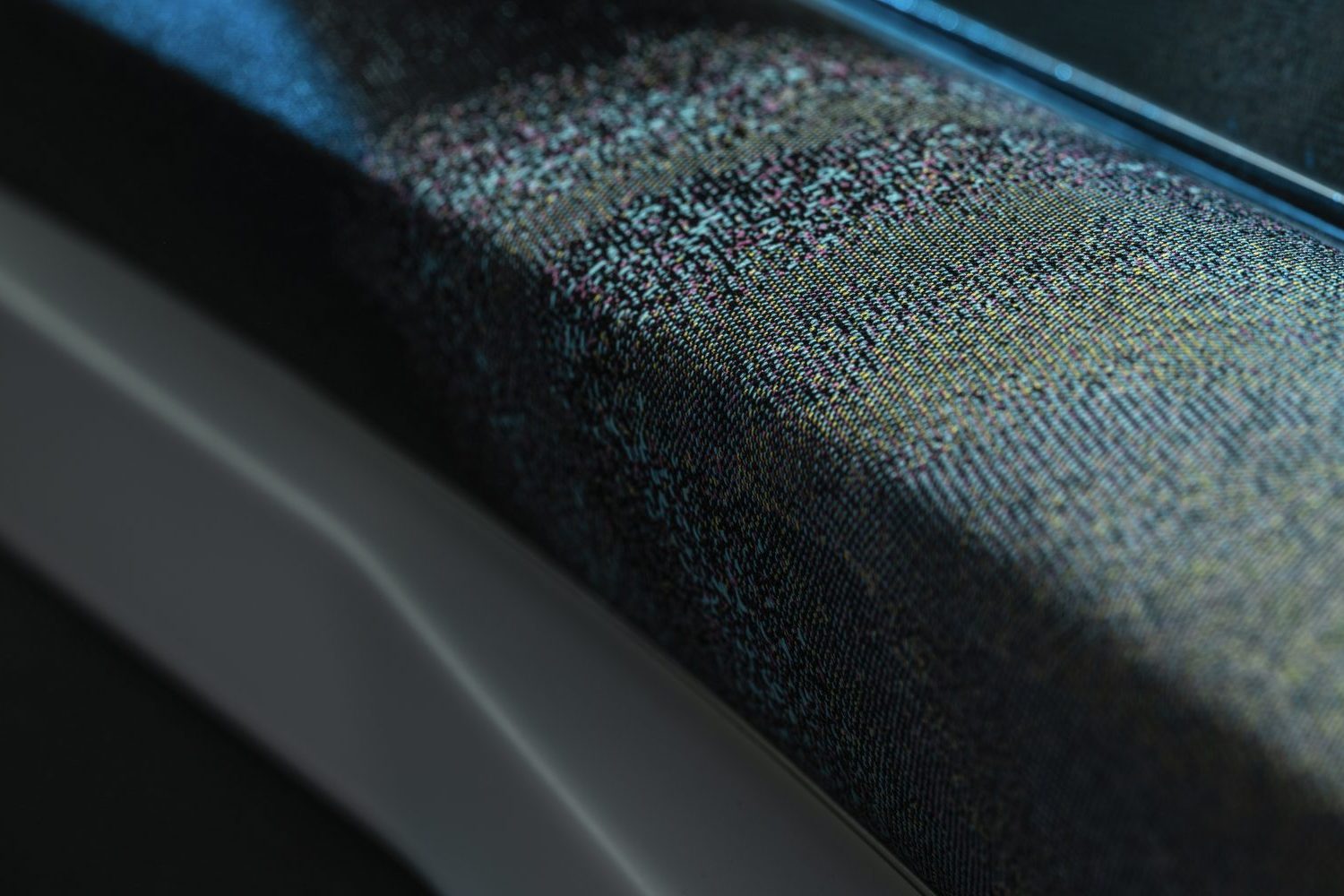

Inside, the cabin is high-tech - check out the full-width 48-inch screen, with a second touchscreen set lower down for easy access - but Renault says that it has tried to create the interior around the idea of 'shy technology' so many of the controls and buttons are carefully tucked behind fabric covers, making the cabin feel softer and more welcoming.

Even the screens are carefully tuned for energy saving - they include automatic deactivation of the LEDs in the black display areas and local dimming. There are some physical controls - thankfully - but these have been kept to a minimum, as it saves carbon if you create software for most of the functions, rather than making physical items.

The Emblème, or vehicles like it, will also be built using low-carbon and carbon-neutral processes. Renault says that it expects a reduction in CO2 emissions from its factories of 62 per cent by 2030. It's also setting up industrial areas where parts and components suppliers are located nearby, minimising the CO2 footprint of each delivered part.

And then there's the recycling. The Emblème is already designed to be built using 50 per cent recycled materials, and when it does come to the end of its life, 90 per cent of the entire vehicle can be recycled again. Renault has already established a new 'refactory' at its historic plant in Flins to develop new and better methods for recycling vehicles and batteries at the end of their lives.

Hopefully someday soon, the innovations shown in the Emblème technology demonstrator will be commonplace on the Renaults you can buy in your local showroom.